A specialised 3D printer for modern dental clinics

DFAB® makes the production of natural-looking dental prosthetics in a far cleaner and simpler process compared to current methods.

Instant Printing

It saves you time by providing an instant personalised 3D printing service that completes the printing of a crown or bridge or veneer in the same inaugural sitting as the first dental scan.

Complete Control

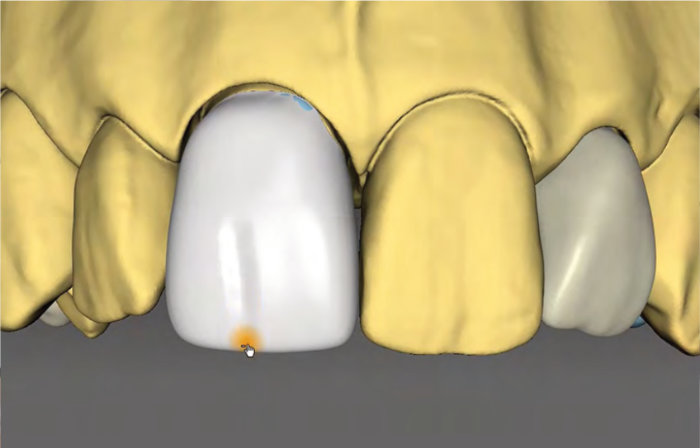

The in-house solution gives total access to the restoration in terms of size, colour, shading, thickness and design parameters directly from intraoral scanning to give even the patient’s exact tooth shade and the most natural result.

High Accuracy and Speed

Thanks to the DFAB’s high high accuracy and precision, DFAB ensures an accurate fit and correct occlusion. Its high printing speed enables the system to produce a bridge with up to five elements in less than twenty minutes.

Advanced Technology that counts

DFAB is no ordinary 3D dental printer; using a sloping print bed and print cartridge the ingenious design provides a continuous flow solution so important for ceramic based processing. Despite the underlying technology DFAB operation is simple and unobtrusive.

Biocompatible Material

DFAB uses disposable cartridges of Irix MAX hybrid ceramic resin which produce aesthetically pleasing permanent restorations that stand out for their translucency, high strength and precise fit.

Permanent Restorations at minimal cost

Producing crowns bridges and veneers that last can be an expensive business. Material costs depend on a number of factors including the number of crowns being produced at the same time but the cost per crown is less than £5 for the fully finished restoration

Silent & Maintenance Free

The 3D printer operates silently and dust-free, and requires no maintenance, installation, or tool changes. Training and on-line support is included

It is available in desktop and chairside versions with integrated computer and 7-inch touch screen.

2 Polymer considered a Class IIa long-term invasive medical device per Rule 5, Annex IX of Medical Devices Directive 93/42/EEC.

3 Alharbi Nawal, Reham Osman, and Daniel Wismeijer. “Effects of build direction on the mechanical properties of 3D-printed complete coverage interim dental restorations.” The Journal of prosthetic dentistry 115.6 (2016): 760-767.

Main Features

- Permanent and provisional restorations in a single visit

- Photoshade Technology: to reproduce the natural color gradient of teeth

- Five materials to meet all needs

- Best user experience thanks to the disposable cartridges and the intuitive interface

- Dedicated Nauta Photoshade software

- Cloud ecosystem for full traceability of procedures, materials, and cartridges

- Functional and elegant minimalist design, awarded “Best of the Best” Red Dot Award 2018

Digital Workflow

DWS developed the technology for DFAB with the primary objective of reducing the time and steps necessary to create dental prostheses, while making the devices easy to control and within reach of operators who do not possess specific in-depth technical knowledge.

Materials

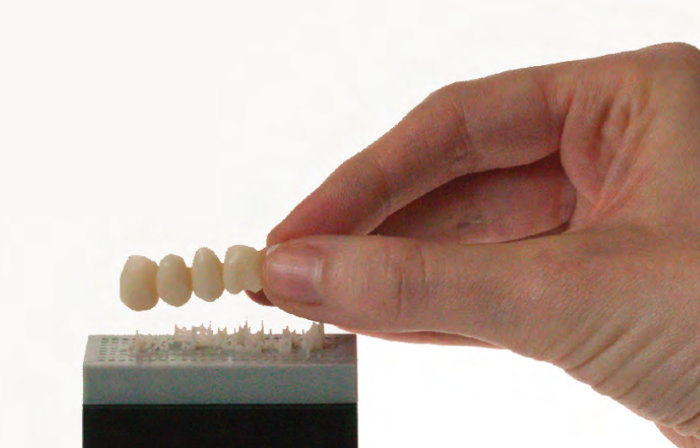

The ready to use disposable cartridges have different sizes for the number of crowns etc. and a range of ever expanding materials that are suitable for permanent restorations.

Photoshade

The included Photoshade software provides a real time shaded preview to enable the most realistic crown colouring.

Finishing Touches

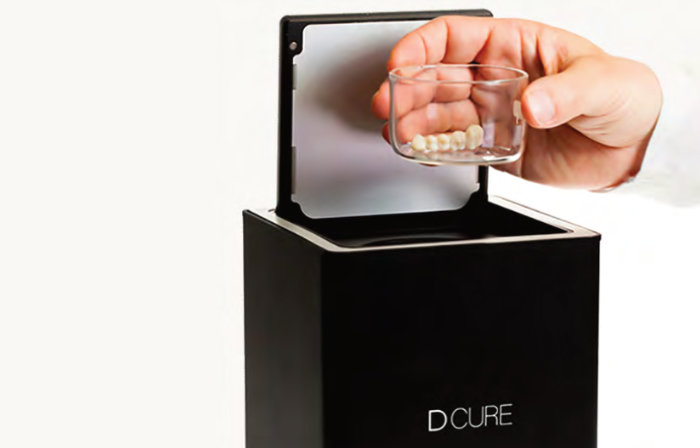

The supports generated by the print are designed to be removed easily and following a brief wash in alcohol and a few minutes of UV treatment the crowns are ready for fitting.

Cementation

Uses dental materials typical for the task such as the 3M or Scotchbond Universal adhesive. In general the use of adhesive adds to the overall crown strength.

Small Footprint

With dimensions of just 30cm (a little over a foot) cubed the DFAB can fit anywhere in the surgery and requires no special connections aside from power and the internet.

A Better Alternative

Advantages of a printed DFAB crown over metal ones include lower wear on adjacent teeth, no need for a temporary restoration, no metal allergies and a cleaner environment.

DFAB Consumables

Revolutionary resin for the production of permanent restorations

Temporis

Composites for provisional direct multiple restorations

- Direct production of partial restorations, provisional customised pillars and crowns, additive restorations with no tooth preparation, provisional direct multiple restorations

- Fast realisation and low operative costs

- Compatible with any glaze and customisation materials

Irix Plus

Hybrid composites with elastic properties for permanent restorations

- Highly elastic restorations also at minimum thicknesses

- High compressive strength values

- High dimensional stability

- Precise fit

- Direct production of partial restorations, customised pillars and crowns, additive restorations without tooth preparation, direct multiple restorations, surgical guides, models with analog, customised healing screws

Iris Max

Highly mechanically resistant hybrid ceramic for translucent permanent aesthetic restorations

- Top of the range aesthetic qualities and mechanical resistance

- High fractural strength that allows reliable and repeatable rehabilitations

- High occlusal wear resistance

- Convenient reconstructions thanks to rapid production and effective finalisation in DCure unit

- Thanks to Photoshade technology the photoreproduction of the natural tooth is possible

- Precise and thin restorations thanks to a mixed structure material similar to the natural tooth

Technical Specifications

The DFAB offers full colour restorations from your desktop, the LFAB can provide monochrome restorations and veneers while the fully portable chairside version has it’s own screen.

Chairside Version

| Technology | Laser – TSLA (Tilting Stereolithography) |

|---|---|

| Working Area | 50 x 20 x 40 mm |

| Laser Source | Solid State BluEdge® |

| Scanning Method | Galvanometer |

| Software | Nauta Photoshade included |

| Input File Format | .stl, .nauta, .fictor |

| Machine Size | 480 x 480 x 1142 mm |

| Weight | 40 Kg |

| Operating Temperature and Humidity | 15°- 25°C / 60% |

| Power Supply | 24V DC with AC 240/220V / 50-60 Hz external supplier included |

| Electrical Consumption | 200W |

| PC Minimum Requirements | Windows 8 or higher* |

| Memory | RAM 4 GB* |

| Graphics Card | OpenGL 2.0 compatible or above* |

| I/O Interfaces | 1 USB port |

| Connectivity | 1 Active internet connection |

*Built-in PC, the minimum requirements are expressed in order to operate Nauta with an external PC (not included).

Desktop Version

| Technology | Laser – TSLA (Tilting Stereolithography) |

|---|---|

| Working Area | 50 x 20 x 40 mm |

| Laser Source | Solid State BluEdge® |

| Scanning Method | Galvanometer |

| Software | Nauta Photoshade included |

| Input File Format | .stl, .nauta, .fictor |

| Machine Size | 300 x 300 x 307 mm |

| Weight | 15 Kg |

| Operating Temperature and Humidity | 15°- 25°C / 60% |

| Power Supply | 24V DC with AC 240/220V / 50-60 Hz external supplier included |

| Electrical Consumption | 160W |

| PC Minimum Requirements | Windows 8 or higher* |

| Memory | RAM 4 GB* |

| Graphics Card | OpenGL 2.0 compatible or above* |

| I/O Interfaces | 1 USB port |

| Connectivity | 1 Active internet connection |

Support

Awesome Technology provides fully inclusive training, installation advice and technical support both on-line and via telephone.